Applications and Optimization Examples of TPS563200DDCR in High-Density Power Modules

The TPS563200DDCR is a highly efficient DC-DC buck converter known for its application in high-density Power module s. This article explores the applications and optimization strategies of the TPS563200DDCR, with practical examples demonstrating its performance, features, and advantages in complex power systems.

TPS563200DDCR, high-density power Modules , DC-DC buck converter, power optimization, power Management , energy efficiency, power density, switching regulators, system integration, power conversion

Introduction to TPS563200DDCR and Its Role in High-Density Power Modules

In today’s rapidly evolving technological landscape, the demand for high-density power modules that deliver exceptional efficiency and reliability has never been greater. The TPS563200DDCR, a DC-DC buck converter from Texas Instruments, has emerged as a key component in addressing these needs, offering a compact, high-efficiency solution for modern power management systems.

The TPS563200DDCR is a step-down (buck) voltage regulator that provides a highly efficient power conversion from a higher input voltage to a lower output voltage. This device is particularly suited for applications requiring both high power density and minimal heat generation, making it ideal for integration into high-density power modules. Let’s explore the features and benefits of the TPS563200DDCR and examine how it optimizes power systems in diverse applications.

Features and Specifications of TPS563200DDCR

The TPS563200DDCR is a synchronous buck converter with a wide input voltage range of 4.5V to 60V and a maximum output current of 2A. It uses a high-frequency, efficient switching mechanism to deliver a stable output voltage with minimal ripple, even at high load currents. This device incorporates several key features that contribute to its success in high-density power modules:

High Efficiency: The TPS563200DDCR features a peak efficiency of up to 95%, which reduces energy losses and heat generation. This is particularly beneficial in high-density power modules, where space constraints often limit the amount of passive cooling available.

Wide Input Voltage Range: The ability to accept input voltages between 4.5V and 60V allows the TPS563200DDCR to be used in a wide variety of applications, including industrial, automotive, and Telecom munications power systems.

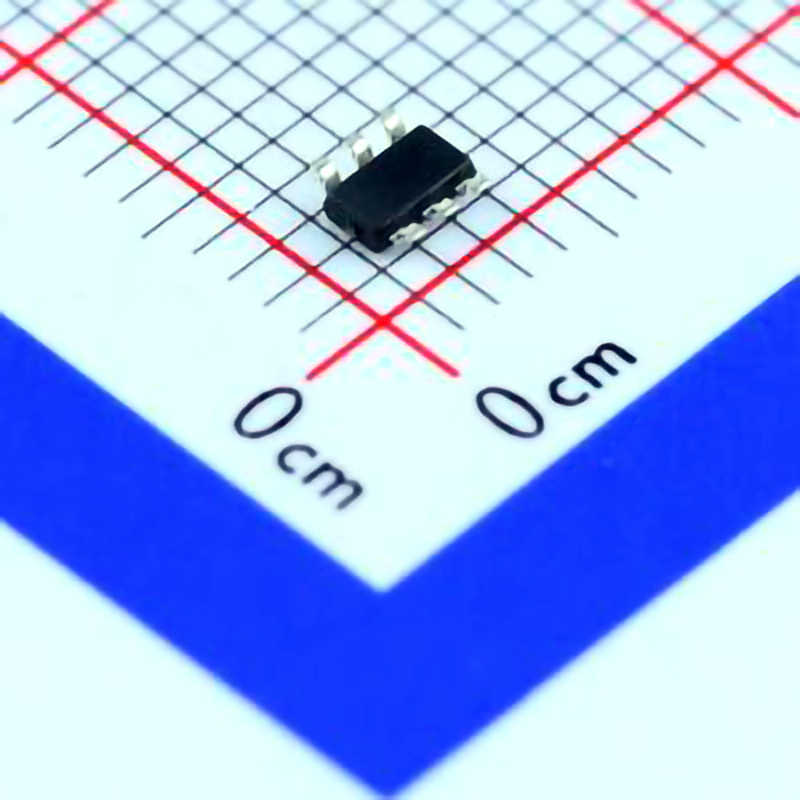

Compact Package: The device comes in a small 3mm x 3mm QFN package, allowing it to be used in designs with strict space requirements. Its small footprint is essential for high-density power modules, where minimizing the size of individual components is critical for optimal performance.

Flexible Output Voltage: The TPS563200DDCR provides adjustable output voltages from 0.8V to 15V, making it suitable for a wide range of end-user applications that require specific voltage levels.

Integrated Features for Simplified Design: The device integrates features like internal soft-start, overcurrent protection, thermal shutdown, and external feedback control, simplifying the design process and enhancing system reliability.

Applications of TPS563200DDCR in High-Density Power Modules

High-density power modules, which are integral to many modern electronic systems, benefit immensely from the incorporation of the TPS563200DDCR. Below are some of the key application areas where this device is making a significant impact:

Telecommunications Equipment

Telecommunications systems require efficient, reliable power supplies to ensure uninterrupted service. The TPS563200DDCR’s ability to deliver high efficiency in a compact form factor makes it an excellent choice for base stations, routers, and switches. These systems often need to support varying input voltage levels and operate in harsh environmental conditions, which the TPS563200DDCR can handle with ease.

Industrial Power Systems

In industrial applications, power modules need to withstand high stress while maintaining low operational costs and minimal thermal output. The TPS563200DDCR is ideal for industrial automation systems, robotics, and control equipment, where power density and efficiency are paramount. Its wide input voltage range and thermal protection features make it a reliable component in high-demand industrial environments.

Automotive Electronics

The automotive industry’s shift towards electrification has led to increased demand for efficient power conversion solutions in vehicles. From electric vehicles (EVs) to advanced driver-assistance systems (ADAS), the TPS563200DDCR provides the low-power, high-density power solutions required in these applications. Its rugged design ensures that it operates reliably in automotive environments subject to high temperatures and voltage fluctuations.

Consumer Electronics

High-performance consumer electronics such as laptops, gaming consoles, and wearables require power modules that are both compact and highly efficient. The TPS563200DDCR fits this requirement perfectly, enabling power supplies in these devices to deliver optimal performance without excessive heat generation, thereby extending the lifespan and reliability of the devices.

Optimization Techniques in High-Density Power Modules

The performance of a power module heavily depends on how well the individual components, such as the TPS563200DDCR, are optimized. Optimization involves improving the overall system efficiency, minimizing noise and ripple, and ensuring stable operation under varying load conditions. Below are several optimization techniques for maximizing the performance of the TPS563200DDCR in high-density power modules:

Minimizing Power Losses

Efficient power conversion is a top priority in high-density power modules, where Thermal Management is often a challenge. To minimize power losses, designers can use high-quality Inductors and capacitor s in the system, ensuring minimal resistance and maintaining smooth power flow. Additionally, choosing low ESR (equivalent series resistance) capacitors can help reduce ripple and improve overall efficiency.

Optimizing Feedback Loops

The feedback loop of a DC-DC converter plays a crucial role in stabilizing the output voltage. By carefully designing the feedback loop and selecting appropriate compensation components, designers can ensure that the TPS563200DDCR responds quickly to changes in load without introducing significant overshoot or oscillations. This is especially important in high-density systems where transient responses must be controlled tightly.

Thermal Management

Given the compact nature of high-density power modules, thermal management is often one of the biggest challenges. Proper placement of the TPS563200DDCR on the PCB, along with the use of heat sinks or copper planes for heat dissipation, can help maintain thermal stability. Additionally, ensuring adequate ventilation and considering the use of thermal vias can help manage temperature rise in high-power applications.

Selecting Appropriate Inductors

Inductors have a significant impact on the performance of a buck converter. The choice of inductor should be based on the desired output current, switching frequency, and efficiency. Low-resistance, high-quality inductors will reduce losses and help optimize the TPS563200DDCR’s performance. Also, keeping the inductor values as small as possible without sacrificing stability can help achieve higher power density in compact modules.

Designing for EMI Compliance

Electromagnetic interference (EMI) is a concern in many applications, especially in densely packed power modules. To mitigate EMI, it is essential to place the TPS563200DDCR in the optimal location on the PCB and use proper grounding techniques. Additionally, shielding and filtering components can be added to reduce the emissions and ensure that the power module complies with regulatory standards.

Real-World Optimization and Case Studies of TPS563200DDCR in High-Density Power Modules

Having discussed the core features and applications of the TPS563200DDCR in high-density power modules, let’s take a deeper look at how real-world systems leverage the device to achieve superior performance and reliability. The optimization strategies highlighted earlier can be put into practice across various industries, with significant improvements in power density, thermal management, and overall system stability.

Case Study 1: Industrial Automation Systems

Industrial automation systems rely on robust power conversion solutions to maintain continuous operation in demanding environments. One example is an automated manufacturing line where sensors, actuators, and controllers require constant and stable power. To ensure that the system functions without interruption, the design team used the TPS563200DDCR to create a high-density power module that would power a wide array of sensors operating at different voltages.

By optimizing the feedback loop for fast transient response, the team ensured that the system would respond quickly to sudden load changes without any significant voltage drops. The wide input voltage range of the TPS563200DDCR also provided flexibility, allowing the system to operate with varying input sources without compromising on performance. Furthermore, thermal management was addressed by carefully placing the converter near the heat sink, utilizing copper pours to dissipate heat effectively.

Case Study 2: Automotive Power Systems

In automotive applications, particularly in electric vehicles (EVs), the need for high-density power modules is critical. One challenge faced by engineers designing power systems for EVs is the size and weight limitations for onboard chargers and power supplies. By using the TPS563200DDCR, engineers were able to integrate a compact yet powerful DC-DC converter into the onboard charger, reducing the overall size and weight of the power module.

The device’s high efficiency minimized energy losses, ensuring that the EV’s battery charging system operated efficiently, reducing the need for excessive cooling and allowing for a longer range between charges. The TPS563200DDCR’s thermal shutdown feature was critical for maintaining safe operation in high-temperature environments, particularly when the vehicle was charging or operating in extreme conditions.

Case Study 3: Consumer Electronics

In the consumer electronics market, the TPS563200DDCR has been employed in applications such as laptops and portable power banks. One specific case involved a portable power bank designed for high-capacity charging. Engineers needed a small, efficient power module to step down the high input voltage from the charging source to power the internal battery management system and various USB ports.

The TPS563200DDCR’s small size, adjustable output voltage, and high efficiency made it an excellent fit. The design team focused on reducing ripple and noise by optimizing the external capacitors and ensuring a stable output under variable loads. The result was a highly compact and reliable power module that provided consistent performance across a wide range of charging scenarios.

Future Prospects of TPS563200DDCR in High-Density Power Modules

As the demand for smaller, more efficient power modules continues to rise, the TPS563200DDCR will play an increasingly important role in shaping the future of power management. With advancements in semiconductor technology and further optimization techniques, we can expect even higher efficiency, lower noise levels, and greater power density from future iterations of this device. Additionally, the continuous trend toward miniaturization in consumer electronics, automotive systems, and industrial automation will drive the need for ever more compact and efficient power solutions, ensuring that the TPS563200DDCR remains a go-to choice for designers.

Conclusion:

The TPS563200DDCR has demonstrated its capabilities as a versatile, high-efficiency power solution in high-density power modules. Through careful optimization of feedback loops, thermal management, and component selection, engineers can unlock the full potential of this device, achieving superior performance in a range of applications. With its compact size, high efficiency, and wide input voltage range, the TPS563200DDCR is poised to remain a key player in the power management industry for years to come.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.