Applications and Thermal Optimization of MP4462DN-LF-Z in High-Efficiency Synchronous Buck Circuits

Introduction to MP4462DN-LF-Z and its Role in High-Efficiency Synchronous Buck Circuits

In the world of Power electronics, efficient voltage regulation is essential for a broad range of applications, from consumer electronics to industrial equipment. One of the most critical components in modern DC-DC converters is the synchronous buck converter, known for its ability to step down voltage with minimal energy loss. Among the many power Management ICs available, the MP4462DN-LF-Z stands out as an excellent choice for high-efficiency synchronous buck converters. This IC is engineered to deliver superior performance while maintaining a small footprint and low thermal output—ideal for both consumer and industrial applications.

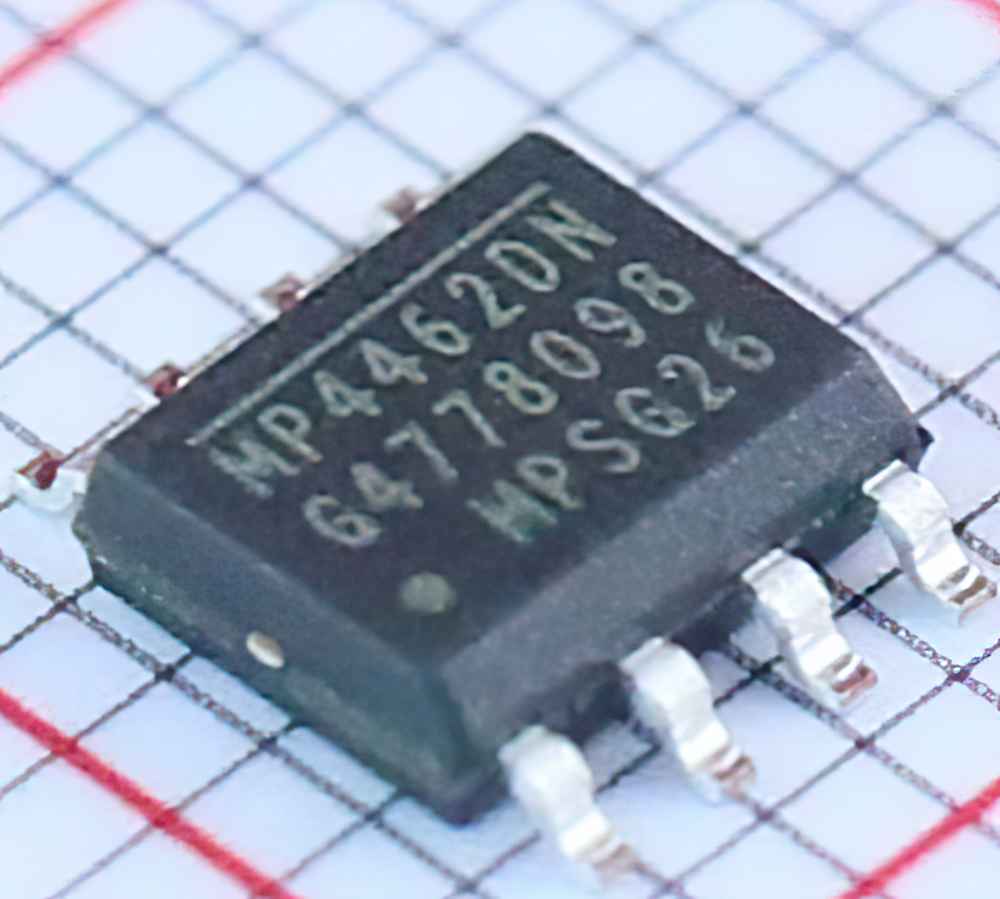

The MP4462DN-LF-Z, a product of Monolithic Power Systems (MPS), is a high-performance synchronous buck regulator designed to operate in applications requiring a regulated output voltage from a higher input. With integrated MOSFETs , advanced control algorithms, and the ability to support high switching frequencies, this IC significantly enhances the efficiency of power conversion while minimizing size and component count.

Key Features of MP4462DN-LF-Z

The MP4462DN-LF-Z is packed with features that make it particularly suitable for demanding high-efficiency power supply designs. Here are some of the standout capabilities:

High Efficiency: One of the primary advantages of this IC is its ability to achieve high efficiency, even under varying loads. The MP4462DN-LF-Z uses synchronous rectification, which significantly reduces conduction losses compared to traditional diodes. The result is higher overall efficiency—often exceeding 90%—which translates to less heat generation and lower power consumption.

Integrated Components: The IC integrates both the high-side and low-side MOSFETs, minimizing the need for external components and simplifying the overall design. This integration contributes to a compact layout, reduced component count, and lower cost.

Wide Input Voltage Range: The MP4462DN-LF-Z supports a wide input voltage range, typically from 4.5V to 60V, making it suitable for a variety of applications, from battery-powered devices to industrial machinery.

Switching Frequency Control: The IC supports adjustable switching frequency, which allows designers to optimize the trade-off between efficiency and size. Higher frequencies can reduce the size of passive components like Inductors and capacitor s, but this may lead to higher switching losses and increased heat.

Soft-Start and Fault Protection: Built-in soft-start functionality ensures that the converter starts up smoothly without stressing components or causing inrush currents. Additionally, features like overcurrent protection, thermal shutdown, and under-voltage lockout enhance the reliability and longevity of the system.

Thermal Performance: Designed to operate efficiently with minimal thermal output, the MP4462DN-LF-Z comes equipped with Thermal Management features to ensure the IC remains within its safe operating range.

Applications of MP4462DN-LF-Z

The MP4462DN-LF-Z is used in a wide array of applications where high-efficiency power conversion is a priority. These include:

Consumer Electronics: Devices like laptops, smartphones, and gaming consoles rely on efficient power supplies to extend battery life and reduce heat generation.

Industrial Automation: High-efficiency DC-DC converters are crucial in machinery and robotics, where reliable power delivery is needed to drive sensors, actuators, and controllers without unnecessary energy waste.

Telecom munications: Network equipment such as routers, switches, and base stations requires power management systems that can maintain stability and minimize energy loss.

Automotive Electronics: Electric vehicles and advanced driver-assistance systems (ADAS) benefit from low-loss, reliable power supplies to ensure efficient operation and long battery life.

Medical Devices: Medical equipment demands high precision and reliability. The MP4462DN-LF-Z's efficiency and thermal management features make it an ideal choice for powering sensitive medical instruments.

Importance of Thermal Optimization

While the MP4462DN-LF-Z excels in terms of efficiency, it is still essential to manage the heat generated during operation, especially in high-current applications. Thermal optimization ensures that the IC operates within its specified temperature range, preventing thermal shutdown or damage. Without proper heat dissipation, the efficiency gains provided by the synchronous buck converter can be negated, and system reliability can be compromised.

Effective thermal management requires a combination of design techniques, such as careful component placement, appropriate PCB layout, and the use of external heat sinks or thermal vias. Additionally, designers can take advantage of the IC's thermal protection features to safeguard the system during over-temperature conditions.

Design Considerations and Thermal Optimization Techniques for MP4462DN-LF-Z in High-Efficiency Circuits

Effective thermal management is one of the most critical factors in maximizing the performance and reliability of high-efficiency synchronous buck circuits using the MP4462DN-LF-Z. In this section, we will explore some best practices and design strategies to optimize thermal performance in systems utilizing this IC.

Key Thermal Considerations in Buck Converter Designs

Power Losses and Heat Generation:

Even though synchronous buck converters like the MP4462DN-LF-Z are highly efficient, there will always be some inherent power losses. These losses can be attributed to factors such as:

Conduction Losses: Resistance in the MOSFETs and inductors causes some energy to be lost as heat.

Switching Losses: The rapid switching of the MOSFETs generates transient heat, especially at high switching frequencies.

Parasitic Losses: Inductors, capacitors, and PCB traces also contribute to overall energy losses.

The goal is to minimize these losses by selecting appropriate components and optimizing the converter design.

PCB Layout and Thermal Management:

A well-designed PCB layout is essential for effective heat dissipation. The MP4462DN-LF-Z comes in a compact package, which can make it more challenging to dissipate heat if not properly managed. To optimize thermal performance, consider the following layout tips:

Thermal Via Placement: Use multiple thermal vias underneath the IC to conduct heat away from the device to the PCB's larger copper planes. This helps spread heat across a larger area and improves overall thermal management.

Copper Plane Area: Increase the size of the ground and power planes to lower thermal resistance. A larger copper area helps dissipate heat more efficiently.

Component Spacing: Ensure that heat-sensitive components are placed away from the MP4462DN-LF-Z to avoid thermal interference. Use proper spacing to allow heat to dissipate freely.

Inductor Selection: Choose inductors with low core losses and low resistance to minimize additional heat generation.

External Cooling Solutions:

In high-power applications, relying solely on PCB thermal management may not be enough. Adding external cooling solutions, such as heat sinks, can further improve thermal performance. Depending on the power level and environment, external heat sinks may be necessary to maintain a safe operating temperature for the IC.

Optimizing Switching Frequency:

Adjusting the switching frequency can have a significant impact on the thermal performance of the converter. While higher frequencies typically result in smaller passive components and reduced system size, they can also lead to higher switching losses and heat generation. Conversely, lower frequencies tend to reduce switching losses but may require larger passive components. Balancing switching frequency with thermal performance and efficiency is a key design decision.

Operating Conditions and Thermal Shutdown:

The MP4462DN-LF-Z includes built-in thermal protection that helps prevent the IC from overheating. However, thermal shutdown should be considered as a last resort, not a primary design strategy. To ensure continuous operation, always design the system with a safety margin, ensuring that the IC operates within safe thermal limits.

Conclusion: Maximizing Performance Through Efficient Thermal Optimization

The MP4462DN-LF-Z is a powerful and efficient solution for synchronous buck converter applications. However, achieving optimal performance requires careful attention to thermal management. By implementing effective PCB layouts, choosing the right components, optimizing switching frequencies, and considering external cooling methods, designers can significantly improve the thermal performance and reliability of their systems.

As power demands continue to increase and devices become more compact, the importance of thermal optimization will only grow. Through thoughtful design and leveraging the MP4462DN-LF-Z's thermal protection features, engineers can ensure that high-efficiency synchronous buck circuits remain reliable, durable, and efficient for years to come.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.