How to Fix LM317T-DG Voltage Regulator Overheating Problems

Understanding the Causes of LM317T -DG Overheating

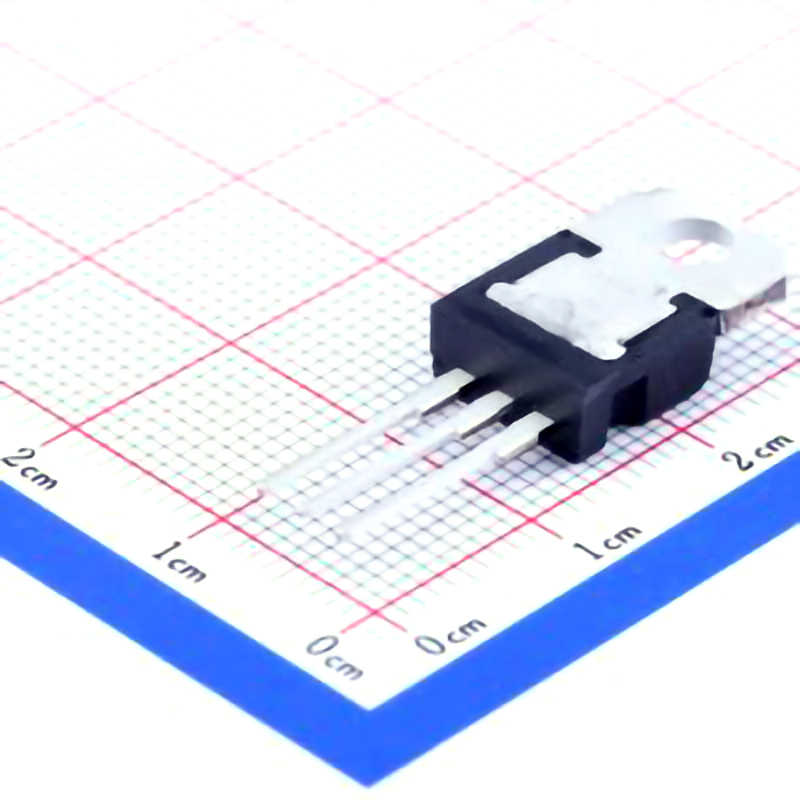

The LM317T-DG voltage regulator is an adjustable, linear voltage regulator used in many Power supply applications. Whether it's in a power supply, charging circuits, or as part of a DIY electronics project, the LM317 T-DG is a popular choice due to its reliability and ease of use. However, one of the common challenges faced by users of this device is overheating. Overheating can lead to a range of issues, including reduced performance, component damage, and even failure. Understanding the root causes of this overheating problem is the first step in solving it.

1.1. Power Dissipation and Heat Generation

One of the main reasons the LM317T-DG can overheat is due to power dissipation. The LM317T-DG is a linear voltage regulator, meaning it regulates the output voltage by dissipating the excess energy as heat. For example, if the input voltage is much higher than the output voltage, the difference between these two voltages is converted into heat within the regulator.

The greater the difference between the input and output voltage, the more heat is generated. This becomes particularly problematic when the current demand is high, as the heat generated will increase proportionally. If the input voltage is significantly higher than the output, the LM317T-DG will have to handle a large amount of power dissipation, which can cause it to overheat if not properly managed.

1.2. Insufficient Heat Sink or Cooling

Another critical factor contributing to the LM317T-DG’s overheating problem is the lack of an adequate heat sink or insufficient cooling. When the LM317T-DG is used in high-power applications, it is essential to provide an efficient method of heat dissipation. Without a heat sink or a way to transfer the excess heat away from the regulator, it can quickly reach dangerous temperatures that can damage the component or cause it to fail prematurely.

1.3. High Current Load

The LM317T-DG can supply up to 1.5A of current, but this is not without consequences. When the current drawn by the load is at or near the maximum capacity of the regulator, the amount of heat produced increases significantly. This issue can be exacerbated when the regulator is used in high-demand applications where the load continuously draws a high current. The increased heat will not only affect the LM317T-DG’s performance but can also shorten its lifespan if proper heat management techniques are not implemented.

1.4. Inadequate Voltage Regulation and Excessive Voltage Difference

Another less obvious cause of overheating in LM317T-DG regulators can arise from improper voltage regulation. If the regulator is set up incorrectly or if there is a significant difference between the input and output voltages, the device may experience stress that leads to excessive heat buildup. This problem can occur when the output voltage is set too high or when the input voltage is too low, forcing the regulator to work harder than necessary.

1.5. Poor Circuit Design and Layout

Lastly, the design and layout of the circuit can also affect the LM317T-DG’s ability to manage heat effectively. For instance, if the regulator is mounted too close to other components or if the PCB layout obstructs airflow, heat dissipation can be impaired. The absence of thermal vias or traces that direct heat away from the regulator can lead to localized overheating, which in turn can affect the overall performance of the circuit.

Practical Solutions to Fix Overheating Problems

Now that we understand the common causes of overheating in LM317T-DG regulators, it’s time to look at practical solutions to fix these problems and ensure that your regulator operates within a safe temperature range. These solutions range from circuit-level improvements to hardware upgrades that can significantly reduce the risk of overheating.

2.1. Use a Suitable Heat Sink

One of the most effective ways to reduce overheating in an LM317T-DG regulator is to use a heat sink. Heat sinks are designed to absorb the excess heat from the regulator and dissipate it into the surrounding air. When selecting a heat sink, make sure it is appropriate for the power dissipation of your regulator. A larger heat sink will be more effective at transferring heat away from the LM317T-DG.

The LM317T-DG has a metal tab on its casing that can be connected to a heat sink for better thermal management. The heat sink should have a low thermal resistance to ensure that it effectively draws heat away from the regulator. In high-current applications, a larger or more efficient heat sink may be necessary to keep the temperature within a safe range.

2.2. Lower the Input Voltage

As mentioned earlier, a large difference between the input and output voltages leads to excessive heat generation. One way to reduce overheating is by lowering the input voltage to be as close as possible to the output voltage. The LM317T-DG works best when the input voltage is only a few volts higher than the output voltage, reducing the amount of energy that needs to be dissipated as heat.

In applications where the input voltage is much higher than needed, consider using a buck converter or a different type of switching regulator instead of the LM317T-DG. Switching regulators are more efficient than linear regulators and generate less heat by converting excess voltage into current.

2.3. Reduce the Output Current Demand

If the LM317T-DG is overheating due to high current demands, you might need to consider reducing the load on the regulator. If the regulator is supplying close to or at its maximum current rating (1.5A), this will generate significant heat. By reducing the current draw of the load or distributing the load across multiple regulators, you can help prevent the LM317T-DG from overheating.

If you need to supply a high current to your load, consider using a different type of voltage regulator that can handle higher currents with less heat dissipation. For example, a buck converter may be better suited for high-power applications where heat is a concern.

2.4. Improve Circuit Layout for Better Heat Dissipation

Improving the circuit layout can also play a critical role in reducing overheating. Ensure that the LM317T-DG is mounted in a way that allows for adequate airflow around the regulator. Avoid placing the regulator too close to other components that may trap heat.

Use thermal vias or copper traces on the PCB to channel heat away from the regulator. The use of a large ground plane can help spread heat across the entire board, reducing hot spots and improving overall thermal management.

2.5. Add External Cooling or Fan Systems

In applications with particularly high power demands or in situations where other thermal management solutions are insufficient, adding external cooling or a fan system might be necessary. Fans can be used to directly blow air over the heat sink, enhancing heat dissipation and lowering the overall temperature of the regulator. This solution is especially useful in environments with poor natural ventilation or in high-performance devices where heat generation is unavoidable.

2.6. Consider Using a Switching Regulator

If the overheating problem persists despite the above fixes, it may be time to consider switching to a switching regulator. Switching regulators, such as buck converters, are much more efficient than linear regulators like the LM317T-DG. Instead of dissipating excess voltage as heat, they convert the excess voltage into usable current, resulting in less heat generation overall. While switching regulators can be more complex to design and implement, they are ideal for high-current or high-efficiency applications where heat is a significant concern.

By understanding the causes of overheating and implementing these practical solutions, you can significantly improve the performance and longevity of your LM317T-DG voltage regulator. Whether through better heat dissipation, optimizing input/output voltage levels, or switching to a more efficient regulator type, these strategies can help keep your power supply running smoothly without the worry of excessive heat buildup.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.