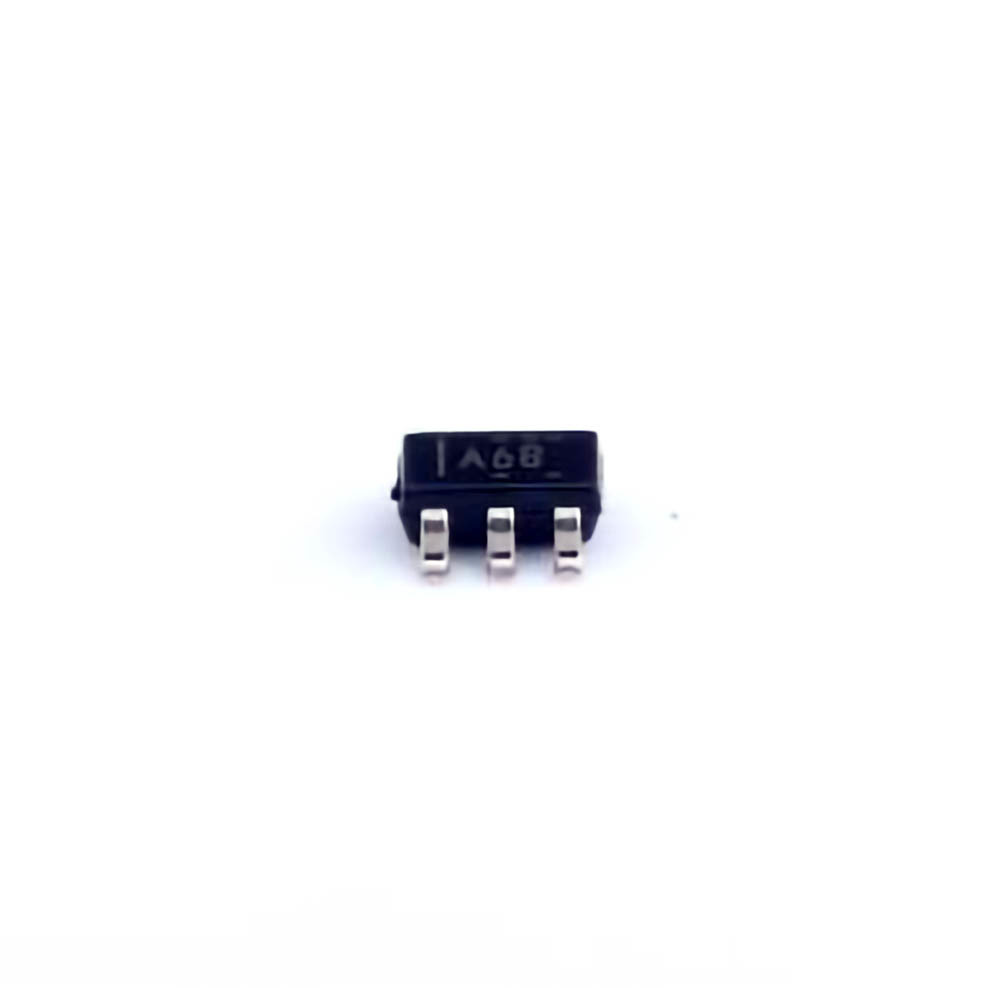

INA168NA/3K Common troubleshooting and solutions

This article explores the common troubleshooting steps and practical solutions for the INA168NA/3K , a high-precision analog-to-digital converter (ADC). By understanding common issues and their resolutions, engineers and technicians can optimize the performance of this device in their designs, saving time and resources. Whether you’re a novice or an experienced professional, this guide will provide valuable insights into the INA168NA/3K’s troubleshooting process.

Understanding the INA168NA/3K and Common Issues

The Texas Instruments INA168NA/3K is a popular analog-to-digital converter (ADC) used in a variety of applications requiring high-precision signal conversion. It is especially well-regarded in industrial applications such as sensor interfacing, measurement systems, and embedded devices due to its accuracy, speed, and low Power consumption. However, like any sophisticated electronic component, the INA168NA/3K is not immune to operational issues. This part of the article will provide an overview of common problems and help you understand how to troubleshoot and resolve them effectively.

1. Power Supply Issues

One of the most common sources of trouble with the INA168NA/3K is a problematic power supply. The ADC is sensitive to voltage fluctuations and noise, which can distort its performance and result in inaccurate measurements or system failure.

Symptoms:

Unstable or erratic ADC output.

High noise levels in the signal.

Failure to initialize the device.

Solution:

Check Supply Voltage: Ensure the supply voltage is stable and meets the recommended levels for the INA168NA/3K. Typically, the operating voltage should fall within the range of 2.7V to 5.5V. Fluctuations outside this range may cause the device to behave unpredictably.

Use Decoupling Capacitors : Place a low-ESR capacitor (typically 0.1μF to 1μF) near the power pins to reduce noise and improve voltage stability. This helps to filter out high-frequency spikes from the power supply.

Check for Ground Loops: A ground loop can introduce noise into the ADC’s measurements, leading to inaccurate conversions. Make sure the ground connections are solid and free of interference.

2. Incorrect Input Voltage or Signal Clipping

The INA168NA/3K is designed to handle a wide range of input signals, but exceeding the voltage limits can lead to signal clipping or damage to the internal circuitry.

Symptoms:

Clipped or distorted output signals.

Missing data or incorrect conversion results.

The ADC may fail to sample or initialize properly.

Solution:

Verify Input Signal Range: Check that the input signal is within the acceptable range. The INA168NA/3K can handle input voltages from 0V to VREF, with VREF typically set to the supply voltage or a reference voltage.

Ensure Proper Scaling: If the input signal is too large, use appropriate scaling techniques such as voltage dividers or operational Amplifiers to reduce the signal to a manageable level.

Use Proper Voltage Reference s: If the signal is approaching the reference voltage or supply voltage, consider using a lower reference voltage to provide a larger margin for input signals.

3. Misconfigured Communication Interface

Many INA168NA/3K users encounter communication issues, especially when integrating the ADC with microcontrollers or other processing units via I2C or SPI. Misconfigurations or incorrect settings can prevent data from being properly read or transmitted.

Symptoms:

No data is being received by the microcontroller.

Communication errors such as timeouts or incorrect data bits.

Inconsistent readings or communication dropouts.

Solution:

Double-Check Communication Settings: Ensure that the I2C or SPI communication parameters, such as baud rate, Clock polarity, and data bits, match between the INA168NA/3K and the host system.

Check Address Configuration: The INA168NA/3K typically uses a configurable address for I2C communication. Make sure the address is set correctly using the relevant hardware or software settings.

Ensure Proper Bus Termination: When using I2C, make sure that pull-up resistors are correctly placed on the SDA and SCL lines. For SPI, ensure that the MISO and MOSI lines are connected properly and that the chip select (CS) pin is functioning as expected.

4. Insufficient or Incorrect Clock Source

The INA168NA/3K, like most ADCs, requires a stable clock signal for proper timing and operation. An incorrect or unstable clock source can lead to timing errors and degraded performance.

Symptoms:

Incorrect conversion rates.

Inconsistent sampling or delayed output.

Failure to initialize or sync with the host system.

Solution:

Use a Stable Clock Source: Ensure that the INA168NA/3K is receiving a clock signal that meets the required frequency and stability. Refer to the datasheet for the recommended clock frequency range and tolerance.

Clock Signal Integrity: Use low-jitter oscillators or crystals for clock generation to minimize timing errors. Poor clock signal quality can introduce noise or distortion in the ADC’s output.

5. Temperature Sensitivity

Environmental temperature changes can affect the performance of the INA168NA/3K, leading to deviations in readings or even system failure if temperature tolerances are not taken into account.

Symptoms:

Drift in ADC readings over time.

Inaccurate measurements in varying environmental conditions.

Failure to maintain consistent accuracy.

Solution:

Monitor Temperature: Keep track of the temperature range in which the INA168NA/3K operates. For best results, ensure that the device stays within the specified temperature range (typically from -40°C to 125°C).

Use Thermal Compensation: In some designs, it may be necessary to implement thermal compensation to account for temperature-related drifts. This could involve calibrating the ADC at various temperatures or using temperature sensors to adjust the output readings.

6. Poor PCB Design and Layout Issues

The layout of the printed circuit board (PCB) can significantly impact the performance of the INA168NA/3K. Poor PCB design can introduce noise, interference, or even damage the device.

Symptoms:

High noise levels in the output signal.

Stability issues or intermittent failures.

Overheating or thermal problems.

Solution:

Optimize Grounding and Trace Layout: Ensure that the ground plane is continuous and as large as possible. Minimize the distance between the device’s ground pins and the PCB ground.

Use Shielding and Isolation: If the device is operating in a noisy environment, consider using shielding to protect the ADC from external EMI (electromagnetic interference). Additionally, isolate sensitive analog signals from noisy digital signals.

Proper Decoupling: Use decoupling capacitors close to the power supply pins of the INA168NA/3K to filter out high-frequency noise and ensure a clean power supply.

Advanced Troubleshooting and Optimization for INA168NA/3K

In this section, we will delve into more advanced troubleshooting techniques and optimization strategies for the INA168NA/3K. These steps are aimed at experienced engineers and technicians who want to fine-tune the performance of their system.

1. Noise Reduction Techniques

Noise is a significant challenge when working with high-precision ADCs like the INA168NA/3K. The following advanced techniques can help reduce noise and improve signal integrity:

Solution:

Differential Input Configuration: If your application involves noisy single-ended signals, consider using the differential input configuration of the INA168NA/3K. This approach helps reject common-mode noise and provides more accurate readings.

Use of Low-Noise Operational Amplifiers : When amplifying the input signal, use low-noise operational amplifiers (op-amps) to prevent additional noise from being introduced into the system.

Shielding: Implementing proper shielding for the ADC and surrounding components is critical in noisy environments. Use metal enclosures or specialized PCB shielding to protect the signal path.

2. Effective Calibration

Calibration plays a crucial role in optimizing the performance of the INA168NA/3K. Over time, drift and component tolerances can lead to inaccuracies. Regular calibration is necessary to maintain precision.

Solution:

Perform Systematic Calibration: Periodically calibrate the INA168NA/3K by using known reference voltages or precision signal generators. Calibrate both the offset and gain parameters to ensure the highest level of accuracy.

Software Calibration: Many systems include software-based calibration routines that compensate for temperature drift and other environmental factors. Implement these routines to ensure that the ADC performs optimally across various conditions.

3. Managing Power Consumption

While the INA168NA/3K is designed for low power consumption, some applications may require even more stringent power management. Optimizing the power usage of the device can significantly extend battery life or reduce overall system energy consumption.

Solution:

Use Sleep Mode: The INA168NA/3K has a sleep mode that minimizes power consumption when the ADC is not actively sampling data. Make sure to enter sleep mode during idle periods to save power.

Dynamic Voltage Scaling: For applications where power consumption is critical, consider dynamically adjusting the supply voltage to the INA168NA/3K based on the system’s requirements. Lowering the voltage when possible reduces power consumption.

4. Handling High-Speed Data Acquisition

The INA168NA/3K is capable of high-speed data acquisition, but to fully take advantage of this capability, careful attention must be given to timing and data throughput.

Solution:

Optimize Data Rate: When using high-speed data acquisition, ensure that your microcontroller or processor can handle the data rate provided by the INA168NA/3K. Buffer the data effectively to prevent loss or timing issues.

Implement FIFO Buffers : For high-throughput applications, use FIFO (First-In-First-Out) buffers to handle bursts of data efficiently. This can reduce the likelihood of data loss or corruption during rapid sampling.

5. Debugging Communication Errors

When troubleshooting communication errors, it’s crucial to perform a systematic analysis of the I2C or SPI bus interactions.

Solution:

Use Logic Analyzers: Use logic analyzers to capture the communication signals on the I2C or SPI bus. This allows you to detect any issues with signal integrity, timing mismatches, or protocol violations.

Monitor Bus Traffic: Monitor the bus traffic for signs of congestion or errors, such as failed handshakes or corrupted data. Address these issues by adjusting communication parameters or optimizing bus performance.

By addressing these common and advanced troubleshooting techniques, you can ensure that your INA168NA/3K operates efficiently and reliably in your electronic systems. Effective troubleshooting not only improves device performance but also extends the longevity of your design, ensuring long-term success in your applications.

If you’re looking for models of commonly used electronic components or more information about INA168NA/3K datasheets, compile all your procurement and CAD information in one place.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.