SPP20N60C3 Common troubleshooting and solutions

Introduction to the SPP20N60C3 and Common Issues

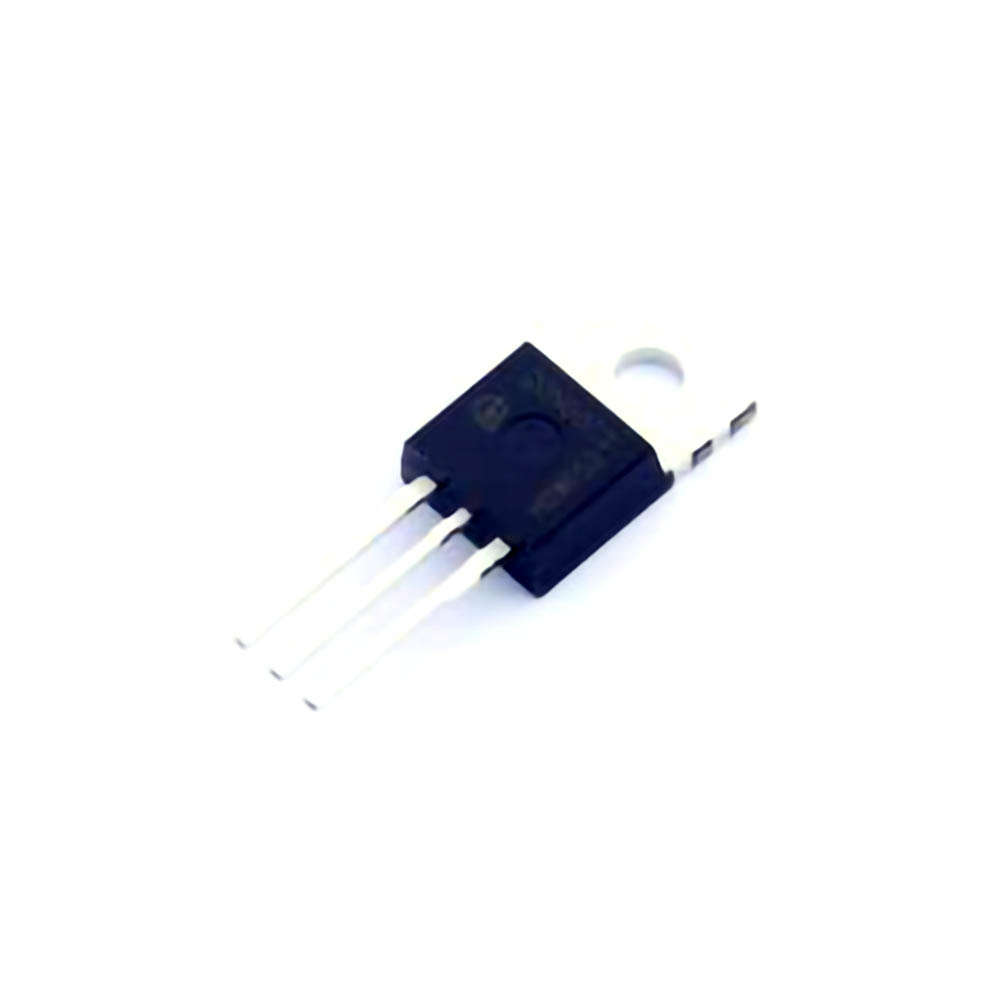

The Infineon SPP20N60C3 is a high-voltage Insulated Gate Bipolar transistor (IGBT) module , commonly used in power electronics for applications such as motor drives, inverters, and power supplies. It combines the ease of control of MOSFETs with the high current and voltage handling capability of bipolar transistors, making it an excellent choice for various industrial applications. However, despite its robust design, users can encounter issues that affect its performance. In this section, we will explore the common problems that may arise with the SPP20N60C3 and how to effectively address them.

1. Overheating of the SPP20N60C3 Module

One of the most frequent issues faced by users of the SPP20N60C3 is overheating. IGBTs operate efficiently within a certain temperature range, and excessive heat can cause thermal breakdown, reduced efficiency, and even permanent damage to the module.

Cause: Overheating can be caused by several factors, including improper cooling, excessive power dissipation, or high ambient temperatures. Insufficient heatsinking or poor airflow around the module can prevent heat from dissipating effectively.

Solution: Ensure that the SPP20N60C3 module has adequate cooling. Use a heatsink that is appropriately sized for the power dissipation requirements of the module. Additionally, ensure proper ventilation or consider using active cooling methods like fans or liquid cooling systems in high-power applications. Always verify the ambient temperature and ensure it remains within the module’s specified range.

2. Short Circuit Failures

Short circuits are a common problem with IGBT modules, and the SPP20N60C3 is no exception. A short circuit can occur when the module’s collector- EMI tter or gate-emitter junctions are bypassed, causing the current to flow in an unintended path. This can lead to significant damage to the module, reducing its operational lifespan.

Cause: Short circuits may arise due to faulty connections, issues with the gate drive circuit, or improper installation. Sometimes, a failure in the load connected to the IGBT module can also trigger a short circuit.

Solution: Check the entire circuit to ensure all connections are correct and securely fastened. Pay particular attention to the gate drive circuitry, as improper gate voltage can cause the IGBT to turn on unexpectedly, leading to a short circuit. Additionally, use protection devices like fuses or circuit breakers to prevent severe damage in the event of a short.

3. Gate Drive Circuit Problems

The gate drive circuit plays a crucial role in switching the IGBT module on and off. Problems with this circuit can cause erratic switching behavior, leading to improper operation or even failure of the SPP20N60C3 module.

Cause: A faulty gate drive circuit can arise from incorrect gate resistor values, inadequate power supply to the gate driver, or damaged gate drive ICs. Inadequate gate drive strength can result in incomplete switching of the IGBT, causing excessive heat generation or unreliable operation.

Solution: Verify the gate drive circuit’s design and ensure that the gate resistor values are in line with the module’s specifications. Also, check the power supply to the gate driver, ensuring it meets the requirements for proper switching. Replacing damaged gate drive ICs or adjusting the circuit may solve the issue. Always refer to the module’s datasheet for gate drive parameters.

4. Latch-Up and Turn-On Failure

Sometimes, the IGBT can fail to turn on or experience latch-up, where the device remains in an active state even after the gate signal is removed. This can lead to inefficient operation and, in the worst case, permanent damage.

Cause: This issue can occur due to excessive gate voltage, poor insulation between the gate and emitter, or incorrect switching conditions. Sometimes, incorrect timing or a mismatch in the voltage levels between the gate and collector can also cause latch-up.

Solution: Ensure that the gate-to-emitter voltage does not exceed the specified limits. It is crucial to use the proper timing in the switching signals to avoid creating conditions that lead to latch-up. Additionally, ensure that the IGBT’s insulation and switching conditions are properly configured, as specified in the datasheet, to prevent latch-up scenarios.

5. Inductive Switching Losses

Inductive switching losses occur when the IGBT turns off while conducting high inductive currents. These losses are particularly problematic in applications like motor drives, where inductive loads are common. These losses can generate excessive heat and reduce the overall efficiency of the system.

Cause: Inductive loads store energy in the form of a magnetic field, and when the IGBT turns off, the collapsing field releases this energy, which causes a high-voltage spike. This spike can damage the module or lead to inefficient operation.

Solution: To mitigate inductive switching losses, use a flyback diode or snubber circuit in parallel with the load. These components help to safely dissipate the energy stored in the inductive load, protecting the IGBT and improving switching efficiency.

Advanced Troubleshooting Techniques and Prevention Methods

Now that we’ve discussed the common issues with the SPP20N60C3 module, let’s dive into more advanced troubleshooting techniques and preventive measures to ensure the long-term reliability of the module.

6. Use of a Thermal Camera for Overheating Detection

If you are unable to identify overheating issues using traditional methods, a thermal camera can be a very useful tool. By using a thermal imaging camera, you can precisely monitor the temperature of various parts of the module and the surrounding circuitry. This allows you to pinpoint hot spots that might indicate poor thermal management or failing components.

Solution: Using a thermal camera, scan the module during operation to detect any abnormal temperature variations. Focus on areas with high power dissipation, such as the collector and emitter leads. If you detect hotspots, increase cooling or adjust the layout for better heat dissipation.

7. Checking for Parasitic Inductances and Capacitances

Parasitic elements such as inductance and capacitance in the PCB layout or wiring can lead to performance issues, especially at high switching frequencies. These parasitics can cause voltage spikes, affect switching times, or result in electromagnetic interference (EMI), leading to system malfunction.

Solution: Perform an in-depth analysis of your PCB layout to minimize parasitic elements. Ensure that the gate trace is as short and direct as possible, and use proper grounding techniques to reduce noise and EMI. Shielding and filtering components can also help to manage high-frequency noise.

8. Routine Inspections and Maintenance

Even though the SPP20N60C3 is designed for durability, routine maintenance and inspections can prevent many issues. Over time, components can degrade, solder joints can weaken, and connections can loosen. By conducting regular checks, you can identify potential issues before they lead to a failure.

Solution: Set up a regular maintenance schedule to inspect the module and the entire system. Check for signs of wear, such as discoloration, cracks, or any damage to the module. Pay attention to the power supply, gate drive circuit, and surrounding components. If any issues are detected, replace or repair the affected parts promptly.

9. Use of Proper Protection Circuits

Protective circuits such as overvoltage protection, under-voltage lockout, and overcurrent protection can help shield the SPP20N60C3 from conditions that could lead to failure. These protection circuits can monitor the operating conditions of the module and ensure it operates within safe limits.

Solution: Incorporate protection circuits in your design to monitor voltage, current, and temperature. These circuits will automatically shut down or reduce the stress on the IGBT if abnormal conditions arise, helping to prevent damage and extending the module’s lifespan.

10. Consulting Manufacturer’s Documentation and Support

When troubleshooting issues, always refer to the manufacturer’s documentation for guidelines and specifications. The SPP20N60C3 datasheet contains essential information on the module’s ratings, recommended operating conditions, and troubleshooting tips. If you encounter issues that cannot be resolved through standard troubleshooting techniques, don’t hesitate to reach out to the manufacturer’s support team for further assistance.

Solution: Always consult the datasheet for exact specifications. If problems persist, contact the manufacturer’s technical support team. They can provide guidance, suggest alternative troubleshooting methods, or even help with repair options if needed.

Conclusion

The SPP20N60C3 IGBT module is a reliable and versatile component widely used in power electronics. However, like any electronic device, it is susceptible to a range of issues that can affect its performance. By understanding the common causes of failure and implementing the appropriate solutions, you can ensure that your IGBT modules perform optimally and have a long operational lifespan. Regular maintenance, careful circuit design, and effective troubleshooting techniques are key to preventing failures and maintaining system efficiency.

If you’re looking for models of commonly used electronic components or more information about SPP20N60C3 datasheets, compile all your procurement and CAD information in one place.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.