Application and thermal management solutions of IRF4905STRLPBF in high-power switching power supply

Introduction to the I RF 4905STRLPBF and Its Role in High- Power Switching Power Supplies

The IRF4905STRLPBF is a robust, high-performance MOSFET that has become a key component in high-power switching power supplies (SMPS). As power electronics continue to evolve to meet the demands of more energy-efficient systems, the need for advanced components like the IRF4905STRLPBF grows significantly. This N-channel MOSFET is engineered for applications that require high current handling and low power losses, making it ideal for demanding power conversion tasks. In this article, we will explore the role of the IRF4905STRLPBF in high-power switching power supplies and the essential thermal Management strategies to ensure its optimal performance.

Understanding the IRF4905STRLPBF MOSFET

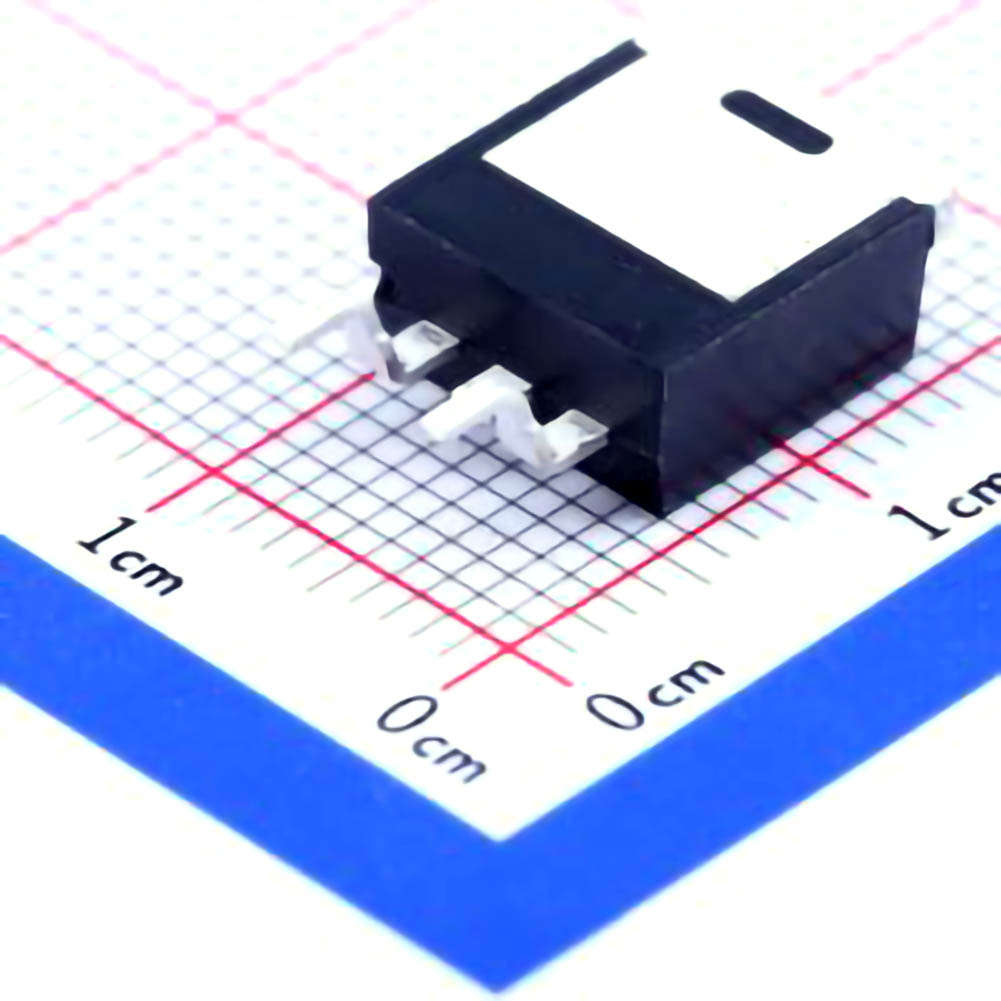

The IRF4905STRLPBF is a MOSFET with impressive specifications that cater to high-power applications. With a Vds (drain-to-source voltage) rating of 55V and a maximum drain current (Id) of 74A, this component is capable of handling substantial amounts of power. These ratings make the IRF4905STRLPBF suitable for use in power supplies that require high current capacities while maintaining excellent efficiency.

In addition to its high power ratings, the IRF4905STRLPBF boasts a low Rds(on) value, which minimizes conduction losses during operation. This characteristic is critical in power supply designs, where minimizing losses leads to better energy efficiency and reduced heat generation. The device’s fast switching characteristics also make it ideal for high-frequency applications, ensuring that switching losses are minimized in power supplies that operate at high speeds.

Applications in High-Power Switching Power Supplies

Switching power supplies are commonly used in a variety of applications, including industrial machinery, telecommunications, automotive power systems, and consumer electronics. The IRF4905STRLPBF MOSFET’s high-current capability and low switching losses make it a perfect fit for these applications. Specifically, it is used in the following areas:

DC-DC Converters : In DC-DC converters, the IRF4905STRLPBF efficiently switches the input DC voltage to a desired output voltage. This functionality is essential in power supplies that need to deliver regulated voltages to sensitive components.

Inverters : The MOSFET is used in inverters for AC power generation from DC sources, such as in renewable energy systems (solar and wind) or uninterruptible power supplies (UPS). Its high switching speed ensures smooth conversion with minimal energy losses.

Motor Drives: In high-power motor drives, the IRF4905STRLPBF is employed to manage power delivery to motors. Its ability to handle large current and switch quickly allows for smooth and efficient control of motor speed and torque.

Power Factor Correction ( PFC ): The IRF4905STRLPBF is often used in power factor correction circuits to improve the efficiency of power conversion systems. By minimizing harmonic distortion and improving efficiency, it helps optimize the operation of power supplies.

Battery Management Systems: In applications like electric vehicles or grid storage, the IRF4905STRLPBF is used in battery management systems (BMS) to manage power conversion between the battery and load, ensuring safe operation and extended battery life.

Key Challenges in High-Power Switching Applications

While the IRF4905STRLPBF provides a solid foundation for high-power switching power supplies, several challenges must be addressed in its application. The most pressing concern in such systems is Thermal Management . As power electronics are subjected to high currents and voltages, they generate significant amounts of heat. If not properly managed, this heat can cause thermal stress on the MOSFET, leading to reduced efficiency, premature failure, and even catastrophic breakdowns. The thermal challenges of high-power switching applications are particularly pronounced in compact systems with limited space for heat dissipation.

Key Factors in Thermal Management for Power MOSFETs :

Conduction Losses: Although the IRF4905STRLPBF features a low Rds(on) value to minimize conduction losses, these losses still exist and contribute to heat generation during operation. High current flows through the MOSFET will generate heat proportional to the Rds(on) and current squared.

Switching Losses: Even though the IRF4905STRLPBF has fast switching characteristics, switching transitions (turn-on and turn-off) still generate heat. This is particularly true in high-frequency applications where the switching frequency can be in the tens or even hundreds of kilohertz.

Ambient Temperature: The environmental temperature where the power supply operates also affects the heat dissipation process. If the ambient temperature is high, the MOSFET’s ability to cool down is impaired, making thermal management even more critical.

Thermal Resistance : The thermal resistance between the junction and ambient plays a critical role in determining the device's maximum power handling capacity. If thermal resistance is too high, it will prevent the MOSFET from dissipating heat effectively, leading to thermal failure.

Thermal Management Solutions for the IRF4905STRLPBF in High-Power Switching Power Supplies

To fully exploit the performance potential of the IRF4905STRLPBF in high-power switching power supplies, it is essential to implement efficient thermal management solutions. These solutions ensure that the MOSFET operates within its safe temperature range and achieves maximum efficiency with minimal thermal stress. Here, we explore the most effective thermal management techniques and strategies to optimize the IRF4905STRLPBF’s performance in real-world applications.

Effective Cooling Methods for Power MOSFETs

Heat Sinks: The addition of heat sinks is one of the most common methods used to increase the surface area for heat dissipation. A well-designed heat sink can significantly lower the temperature of the IRF4905STRLPBF by providing an efficient path for heat transfer from the MOSFET to the surrounding environment. When selecting a heat sink, factors such as material (typically aluminum or copper), size, and surface finish (e.g., fins or pins) should be considered to maximize the heat dissipation capability.

Active Cooling with Fans: In environments where passive cooling (e.g., heat sinks) may not be sufficient, active cooling solutions such as fans or forced air cooling can be implemented. Fans increase the airflow around the MOSFET and its heat sink, thereby enhancing the heat transfer process. For high-power applications where the power density is high, active cooling ensures that the system remains within safe operating temperatures even under heavy loads.

Thermal interface Materials (TIMs): The use of thermal interface materials (TIMs) between the MOSFET and heat sink is crucial for improving thermal conductivity. Materials such as thermal pastes or pads reduce the thermal resistance at the junction between the MOSFET and the heat sink, ensuring efficient heat transfer. Selecting high-quality TIMs with low thermal resistance is essential for minimizing thermal buildup.

Liquid Cooling Systems: For the most power-dense systems, liquid cooling is an option. This involves circulating a coolant (usually water or a glycol mixture) through a cold plate attached to the MOSFET or through a heat exchanger in close proximity. Liquid cooling provides a highly efficient method for managing thermal loads in extremely high-power applications, such as industrial machinery, servers, or electric vehicle systems.

PCB Thermal Design: The design of the printed circuit board (PCB) plays a crucial role in the thermal performance of the IRF4905STRLPBF. Implementing wide, thick copper traces for power paths and proper via placements for heat dissipation can effectively spread and channel heat away from the MOSFET. Additionally, careful attention to the layout can help minimize the thermal hotspots that could result from poor heat distribution.

Thermal Monitoring and Protection: In high-power systems, it is essential to monitor the temperature of the MOSFET and other critical components in real-time. Implementing temperature sensors and thermal protection circuits ensures that if the temperature exceeds a predefined threshold, the system can take corrective action, such as reducing load or shutting down to prevent damage. Many modern power supplies integrate temperature sensing and thermal shutdown features to protect sensitive components from overheating.

Optimizing Efficiency Through Thermal Management

Effective thermal management not only ensures the safety and longevity of the IRF4905STRLPBF but also contributes to the overall efficiency of the power supply. By minimizing the thermal losses in the system, the overall efficiency is improved, reducing the amount of energy wasted as heat and improving the performance of the entire power supply.

Minimizing Switching Losses: One of the most significant sources of heat in high-power switching applications is switching losses. These losses are particularly prominent at high switching frequencies. To minimize these losses, designers can choose the IRF4905STRLPBF with the lowest possible switching times and optimize gate drive circuitry. By using advanced gate drivers, it is possible to reduce the switching losses and, in turn, the heat generated by these transitions.

Operating at Lower Junction Temperatures: By ensuring that the IRF4905STRLPBF operates at lower junction temperatures, it is possible to achieve better overall performance. This includes reducing Rds(on) and minimizing thermal runaway, a phenomenon where increasing temperature causes the MOSFET’s resistance to increase further, leading to more heat generation in a positive feedback loop. By optimizing thermal management, the MOSFET can stay within its ideal operating temperature range, ensuring minimal losses and extended life.

System-Level Thermal Management: At the system level, thermal management strategies should be integrated to ensure that the entire power supply, including its other components, operates efficiently. This might involve using temperature gradients or heat pipes to direct heat from other power components to areas of the PCB that have been optimized for heat dissipation. By ensuring that all components are efficiently cooled, designers can improve the overall reliability and efficiency of the system.

Conclusion: Achieving Reliable, High-Performance Power Supply Solutions

The IRF4905STRLPBF MOSFET offers significant advantages in high-power switching power supplies, with its high current handling, low switching losses, and excellent efficiency. However, the key to unlocking its full potential lies in effective thermal management. By leveraging solutions like heat sinks, active cooling, and optimized PCB design, engineers can ensure that the IRF4905STRLPBF operates efficiently and reliably, even under high-power conditions. Proper thermal management not only improves system reliability but also enhances overall efficiency, contributing to energy savings and longer-lasting power supplies.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.