Optimization Solutions of SN65HVD1781DR in Industrial RS-485 Communication

Understanding the Role of SN65HVD1781DR in Industrial RS-485 Communication

In the world of industrial automation, communication networks are the backbone of every process, from factory automation to control systems. The need for reliable, high-performance communication protocols in these environments is paramount. RS-485, a differential signaling standard, is widely used for its robustness in noisy industrial settings and its ability to support long-distance communication. Among the key components that ensure the smooth operation of these networks is the SN65HVD1781DR, a highly optimized transceiver designed for industrial RS-485 applications. This part of the article will examine the significance of RS-485 communication and explore how the SN65HVD1781DR enhances network performance.

1.1 RS-485 Communication: The Backbone of Industrial Networks

RS-485 is a differential communication standard that is known for its noise immunity and long-distance capability, making it ideal for industrial applications. Unlike traditional single-ended systems like RS-232, RS-485 uses differential signals, where data is transmitted as the difference between two signals rather than the voltage level relative to ground. This differential nature minimizes the impact of electrical noise and allows RS-485 systems to operate over long distances (up to 1200 meters) at high speeds.

Industrial environments are prone to electromagnetic interference ( EMI ) due to heavy machinery, motors, and various Power equipment. RS-485’s robustness against EMI makes it the protocol of choice for industrial control systems, automation networks, and remote monitoring. It supports multi-point configurations, allowing up to 32 devices to be connected on a single bus, enabling communication with multiple machines and sensors at once.

1.2 The Role of Transceivers in RS-485 Networks

At the heart of every RS-485 communication network is the transceiver. A transceiver is a device that combines both the transmitter and receiver functions in one component. In industrial environments, where reliability and durability are crucial, choosing the right transceiver is essential. The transceiver handles the conversion between the logic-level signals generated by a microcontroller or processor and the differential voltage signals used for communication over the RS-485 bus.

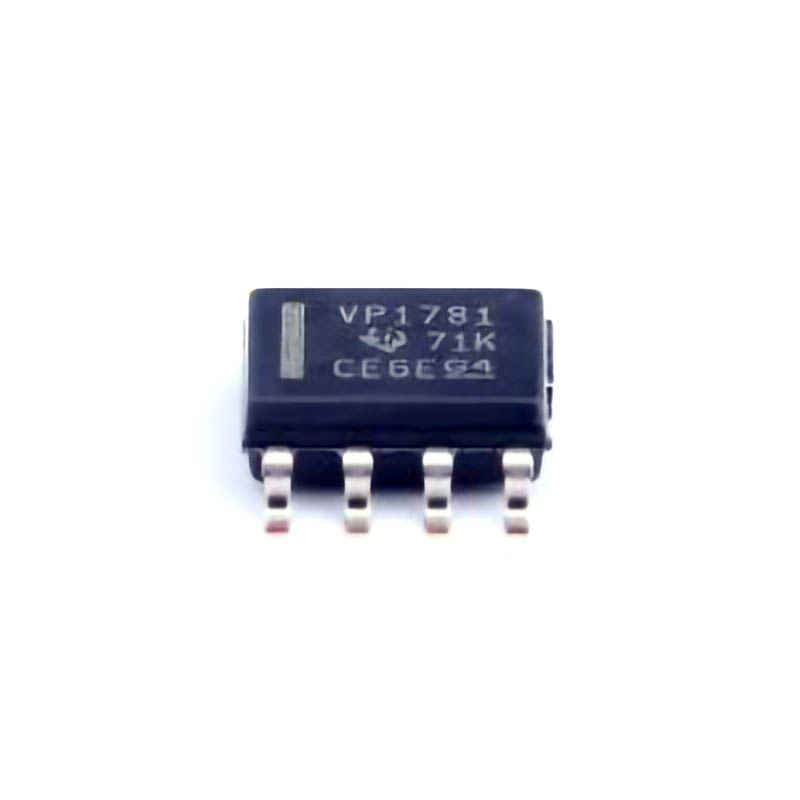

The SN65HVD1781DR, developed by Texas Instruments, is a state-of-the-art RS-485 transceiver that offers several advantages over traditional solutions. Its optimized design focuses on improving data transmission integrity, increasing efficiency, and ensuring long-term reliability, which are all crucial in industrial applications.

1.3 Key Features of the SN65HVD1781DR

The SN65HVD1781DR is designed to operate in harsh industrial environments, offering key features that make it stand out in the RS-485 communication space:

Low Power Consumption: Power efficiency is a critical factor in industrial systems, where devices need to operate around the clock. The SN65HVD1781DR is engineered to consume minimal power while maintaining high performance. This helps in reducing overall system power consumption, which is particularly important for large-scale industrial networks.

High Data Rate Support: The transceiver supports data rates of up to 20 Mbps, making it suitable for high-speed communication applications. Whether it's for real-time data monitoring or control commands, the SN65HVD1781DR ensures reliable and fast communication between devices.

Wide Operating Voltage Range: The SN65HVD1781DR can operate over a wide voltage range (from 4.75V to 5.25V), making it versatile and adaptable to various industrial system voltages.

Enhanced ESD Protection: Electrostatic discharge (ESD) protection is a major concern in industrial environments, where equipment is frequently exposed to shocks. The SN65HVD1781DR features robust ESD protection, ensuring that the transceiver continues to operate reliably even under adverse conditions.

Fail-Safe and Bus Fault Protection: The transceiver offers fail-safe design features that ensure the network remains operational even in the event of a bus fault, such as an open circuit or short. This is essential for ensuring uninterrupted communication in critical industrial applications.

1.4 How the SN65HVD1781DR Enhances RS-485 Networks

The key to optimizing an RS-485 network lies in ensuring that the communication remains stable, efficient, and resilient to external disturbances. The SN65HVD1781DR improves these parameters in several ways:

Improved Signal Integrity: The high-speed differential signaling supported by the SN65HVD1781DR ensures that data is transmitted over long distances with minimal signal degradation. This is particularly important in large industrial facilities where signal attenuation and distortion can occur.

Noise Immunity: The transceiver’s design minimizes the impact of external noise, which is common in industrial environments. By maintaining strong noise immunity, the SN65HVD1781DR ensures reliable data transfer in systems with heavy electromagnetic interference.

Support for Multi-Drop Networks: The SN65HVD1781DR allows for the connection of multiple devices on the same communication bus, which is a critical feature for industrial automation systems that require the monitoring and control of numerous devices. The ability to support up to 32 devices without signal degradation ensures scalability and flexibility in network design.

Reduced Power Consumption: The low-power design of the SN65HVD1781DR translates into less energy consumption, which is a crucial factor in industrial applications that run 24/7. This helps in reducing operational costs and enhancing the sustainability of the communication system.

1.5 Applications of SN65HVD1781DR in Industrial Systems

The SN65HVD1781DR is ideal for a wide range of industrial applications, where reliable, high-performance communication is essential. Some common use cases include:

Factory Automation: The transceiver ensures smooth communication between programmable logic controllers (PLCs), sensors, actuators, and human-machine interface s (HMIs) in automated production lines.

Remote Monitoring: Industrial systems often require monitoring over long distances, such as for energy management or environmental monitoring. The SN65HVD1781DR’s long-range capabilities make it ideal for connecting devices over large areas.

Process Control Systems: In applications such as chemical processing or power plants, the transceiver helps in maintaining seamless communication between controllers, sensors, and monitoring equipment.

Optimizing Industrial RS-485 Networks with SN65HVD1781DR

Building on the foundational understanding of RS-485 and the SN65HVD1781DR’s features, this section explores optimization strategies for integrating and utilizing the transceiver in industrial networks. By focusing on advanced solutions, network design considerations, and real-world performance enhancements, we can unlock the full potential of RS-485 communication with the SN65HVD1781DR.

2.1 Designing Robust RS-485 Networks with the SN65HVD1781DR

The first step in optimizing an industrial RS-485 network is selecting the right components. While the SN65HVD1781DR transceiver is a powerful choice, its integration into the broader system design requires careful consideration of several factors:

Termination and Biasing: In an RS-485 network, proper termination and biasing are essential to prevent signal reflections and ensure the integrity of data transmission. The SN65HVD1781DR supports robust termination techniques, but engineers must design the network with appropriate resistors at both ends of the bus to minimize reflections and impedance mismatches.

Multi-Drop Configuration: When designing a multi-drop RS-485 network, it’s essential to ensure that devices are properly placed on the bus, maintaining the necessary distance and avoiding excessive loading. The SN65HVD1781DR’s capability to support up to 32 devices allows for flexible system design. However, system designers should ensure that devices are correctly terminated and properly biased for optimal performance.

Grounding and Shielding: Industrial environments are prone to electrical noise, and grounding and shielding play critical roles in ensuring stable RS-485 communication. The SN65HVD1781DR transceiver benefits from its enhanced noise immunity, but grounding the network correctly and using shielded cables can further reduce noise and improve communication stability.

2.2 Leveraging the SN65HVD1781DR’s Power Efficiency

In large-scale industrial systems, power efficiency is a key concern. Devices like the SN65HVD1781DR, which operate with low power consumption, help reduce overall system energy usage. Here’s how this can be maximized:

Low Power States: The SN65HVD1781DR features an automatic low-power shutdown mode when idle, helping to reduce the overall energy consumption. Leveraging this feature in industrial designs can result in significant energy savings, especially in systems that run continuously.

Energy Harvesting: Some industrial networks, such as remote sensors in agriculture or environmental monitoring, rely on energy harvesting techniques to power devices. With its low power requirements, the SN65HVD1781DR can be integrated into such systems to optimize energy consumption without compromising communication performance.

2.3 Improving Network Scalability and Performance

As industrial systems grow, the need for scalable communication networks becomes essential. The SN65HVD1781DR’s ability to support up to 32 devices on the same bus is ideal for scalable designs. However, maintaining performance over a growing network requires addressing the following challenges:

Signal Integrity: As the number of devices increases, so does the potential for signal degradation. Ensuring proper network design, with adequate termination, biasing, and the use of repeaters when necessary, will help maintain signal integrity across long distances and multiple devices.

Network Topology: Choosing the right network topology is crucial for large-scale RS-485 networks. The SN65HVD1781DR supports both bus and star topologies, but a well-planned bus topology generally offers better scalability and simpler installation.

2.4 Real-World Benefits in Industrial Applications

The performance enhancements provided by the SN65HVD1781DR are evident in real-world industrial applications. From factory automation to remote monitoring, the transceiver’s reliability and efficiency deliver significant improvements:

Improved System Reliability: The SN65HVD1781DR's fail-safe design ensures that the RS-485 network remains operational even in the event of a bus fault, providing industrial systems with enhanced uptime and reliability.

Faster Data Transfer: The ability to transmit data at speeds up to 20 Mbps means that systems that require real-time data exchange—such as in automated manufacturing or robotics—benefit from faster, more efficient communication.

Reduced Downtime: With the SN65HVD1781DR’s enhanced protection features, including ESD and fault protection, industrial systems experience fewer disruptions, reducing maintenance costs and downtime.

Conclusion

The SN65HVD1781DR transceiver plays a pivotal role in optimizing industrial RS-485 communication systems. Its low power consumption, high data rate support, and exceptional noise immunity make it an ideal choice for modern industrial networks. By integrating this transceiver into system designs and optimizing network topology and configuration, industrial applications can enjoy improved communication performance, enhanced reliability, and greater scalability.

Through a combination of thoughtful design and leveraging the advanced features of the SN65HVD1781DR, industries can take full advantage of RS-485’s potential in powering robust, efficient, and long-lasting communication networks.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.